Custom packaging box design services

Being a Master Box Maker is to master a set of techniques necessary for custom packaging design and realization of the most complex packaging projects.

For more than thirty years, Laklé has been sharing its expertise with you and offering a complete range of specialized technical services.

Check out the complete list of our custom packaging services and do not hesitate to contact our sales representatives to learn more.

There are several packaging manufacturers, but few can be as creative as Laklé.

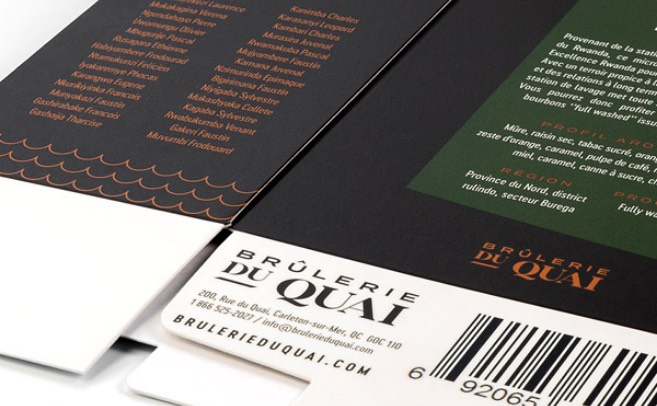

Hot Stamping services

If you’re looking to add a touch of luxury and elegance to your custom packaging design, you’ll want to know a little more about the hot stamping solution.

Hot stamping process is a finishing technique widely used by packaging manufacturers in which a thin pigmented or metallic foil is pressed against a surface, such as cardboard, paper, plastic or leather, using a hot plate.

This causes the pigment or metal to transfer to the chosen surface. With its metallic sheen, available in thousands of colors, hot stamping will add a luxurious touch of elegance to your custom packaging design.

Embossing Services

Embossing is a solution that aims to raise selected parts of a package in order to highlight them on thin paper or cardboard.

This manufacturing process offers a 3D effect to your custom packaging design, as well as a luxurious look to your packaging.

Following the same principle, debossing is based on the production of embossed effects, but in reverse; that is, with an inverted relief pattern.

Depending on the material on which it is used, the tactile relief provided by the embossing and debossing techniques will give your documents prestige and style.

Note that these two solutions work very well together for an even more pronounced tactile aspect.

The addition of embossing will also offer a touch of prestige and luxury to your packaging.

Prototyping Services - A simple and efficient process

The design and production of a new packaging solution is sometimes complex. Several parameters must be considered: the choice of the right cardboard, the strength of the finished product, the ease of assembly of the box, the choice of material used to hold the products in place (insert or divider) and much more.

You will appreciate our prototyping services that will allow you to validate your packaging BEFORE the final production process.

All packaging box design projects go through the prototyping stage in order to validate the idea; the appreciation of a concept’s accuracy. Our prototypes are made in real size with the right materials that will be used in the final production of your custom printed box.

This step will allow you to concretely validate all aspects of the packaging box design (formats, materials, design, assembly, etc.) and to present it to your team. In addition, they allow you to make all the necessary validations before starting the production process.

From the prototype, our design department makes sure that all the little details are taken care of so that your custom box or display will perfectly meet the production parameters. Nothing is left to chance!

Gluing services

Also known as “Laminating”, this technique refers to the assembly of two materials using a glue or adhesive. The assembly of various materials is sometimes the best way to obtain the desired product.

Laklé uses two gluing techniques for its packaging box design solutions, depending on the needs:

- "Paper to board gluing": to obtain the high quality of the offset or digital printing of the paper and the structural rigidity of the board.

- Cardboard to cardboard gluing": to obtain a very high level of rigidity and an impeccable finish.

Our specialized equipment and our technical knowledge of various materials allow us to offer you innovative assembly solutions that will meet your most varied needs.

Cutting and Decorating Services

Using highly specialized equipment, Laklé offers “automatic die-cutting and stripping” of various shapes on flat board, corrugated board and paper. These presses allow a very high speed of execution and a high level of precision.

For smaller projects and packaging box design solutions, Laklé also offers manual die cutting and stripping services. Regardless of the size of your project, Laklé has the expertise and equipment necessary to create high-quality custom packaging designs that meet your specific needs.

Digital cutting services

Very large formats for ambitious projects!

Digital cutting involves precision cutting without the use of dies. This method offers the same advantages as traditional cutting, but uses blades and bits to allow very precise cuts, grooves and/or folds if necessary. It is perfect for small quantities or very large format.

The benefits of digital cutting

The biggest advantage of digital cutting, of course, is that it does not require the fabrication of a conventional die. A much shorter turnaround time is then possible.

Other key benefits include:

- Great versatility: Laklé's digital tables can cut different materials up to a size of 65'' x 120''; something traditional cutting machines cannot offer;

- Cost reduction: Since no die form is used in digital cutting systems, there is no cost associated with the manufacturing and use of a conventional die. This makes the process more economical for smaller production runs than die cutting;

- High precision: Digital die cutting is very precise, as it uses very small bits or blades.

- Digital cutting allows for shorter turnaround times, while ensuring a clean and accurate output.

Various materials used in digital cutting

Digital cutting tables are very versatile and can be used for many different types of materials, such as textiles and paper for packaging box design.

Commonly worked materials include:

- Vinyl;

- Cardboard / Paper / Foamboard / Reboard;

- Leather;

- Composite materials (such as reinforced plastic);

- Foam;

- Canvas;

- ACM, etc.

This flexibility allows the creation of all kinds of products and parts.

Automatic folding and gluing services

The automatic folding and gluing service consists of transforming a flat material into a finished product such as a box, an envelope or promotional material.

The process is simple: the automatic press folds the material along groove lines, and glue are applied to specific areas to hold the product in place.

Folder-gluers accept a wide range of materials, including flat cardboard, plastic, corrugated cardboard, etc. Used primarily in the packaging industry, these presses transform blanks into conventional boxes, with self-closing bottoms, etc.

In addition, our ultra-fast automated folding and gluing equipment allows us to produce large runs in a very short time.

This production capacity allows us to meet the shortest deadlines.

Manufacturing and blade change service for cutting dies

When it comes to packaging box design, Laklé’s expertise is well established. With the design and production of thousands of cutting dies, for projects ranging from simple cardboard sleeves to the most complex packaging, Laklé offers a complete and unparalleled service for manufacturing and changing die blades.

Die-cutting dies have a shelf life. The blades must be changed after a certain run. The length of use varies according to the quantity of pieces cut, but also according to the material being cut.

In either case, it will be necessary to change the blades or bearings. In some cases, we can modify the shape of a blade to obtain a better fit and more precision.

Laklé offers complete services of manufacturing or correction of dies: its expertise in press cutting allows us to offer solutions adapted to your equipment. Even professionals such as ghostwriter schweiz (“Ghostwriter Schweiz” means Swiss ghostwriter in German) appreciate this precision when working on high-standard packaging projects.

Other custom packaging services offered by Laklé :

- Manual finishing (gluing, magnets, cellophane wrapping, boxing, calendar strapping, etc.);

- Plastic / cardboard card placement (tipping) such as credit cards, gift cards, etc;

- Flat die-cutting and manual stripping;

- Final assembly;

- Manual gluing of boxes and other items (cold glue / hot glue);

- Dieline correction;

- Manufacturing of cutting dies;

- Insertion of your products in packaging.

Some satisfied clients

Wow, what amazing work once again! Thank you to the whole team.

I’d like to take this opportunity to thank you and your team for your support and invaluable collaboration ☺️ You’re doing an excellent job, and we truly appreciate it.

The event at Volkswagen went really well, and there were a lot of positive and impressive comments… about the Mille Bornes game! It was the highlight of the evening for many people!

Thank you all for your efficiency in turning things around to help us this week!

They are stunning!! A huge thank you for everything! I will definitely keep your contact for future projects.